Insulated Roll-up Door

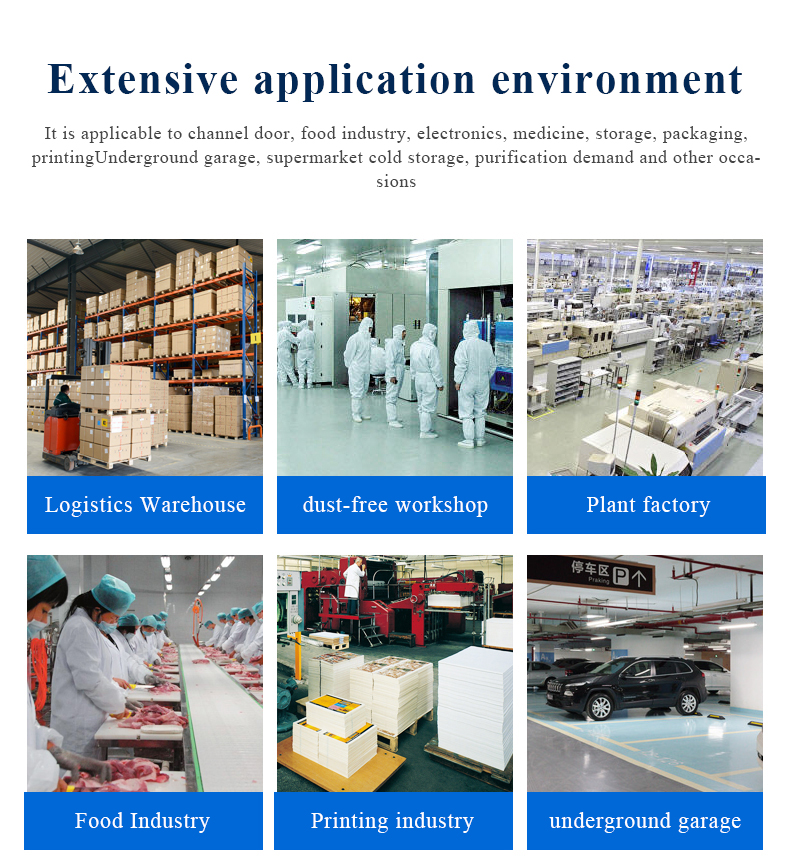

Insulated Roll-up Door is a fast rise and fall barrier-free isolation door, the main function is to help maintain a constant temperature, constant humidity, clean working environment at certain places. It is applied in food industry, electronics industry, auto industry, logistics etc.

- Product details

Product parameters

Product parameters1. Product introduction

Quick door is a barrier-free isolation door with rapid lifting. Its main functions are heat preservation, moisturizing, dustproof, insect-proof, soundproof, etc., so that the workshop can maintain a constant temperature, constant humidity and clean working environment. It is suitable for food, medicine, electronics, rubber, chemical industry, automobile, textile, logistics and other fields.

2. Working principle

Quick door belongs to automatic control equipment, which is composed of door frame, PVC curtain, drive motor and control system. Fast rolling door

Lifting speed: 0.7m / s-2.1m / s, generally about 2 seconds from the bottom to the top (the speed is 20 times that of the electric rolling gate), vehicles and pedestrians do not need to wait, and do not constitute an obstacle.

There are many ways to trigger the door open signal: manual button, radar sensor, infrared photoelectric sensor, geomagnetic sensor, remote control, etc.

Door cloth material: PVC is generally used as the curtain cloth, PVC membrane material has better anti-aging performance, is not easy to fade, and has self-cleaning function. It is very suitable for fast rolling door. The origin is made in Germany or France. Thickness 0.8mm-2.0mm.

Color: orange, yellow, blue, silver, transparent, gray, etc. Orange is the first choice, because orange is very eye-catching, has a warning function, and has a certain anti-insect function.

Drive motor: The fast rolling door uses brake deceleration motor, which requires fast braking and low noise. Generally, the brake motors sold on the market are either not good in braking effect or very loud in braking noise, which are not suitable for fast rolling doors. A speed ratio of 1: 10-1: 15 is more appropriate.

Working process: The trigger signal is provided by the door opening sensor to the control system. The control system sends a command to the inverter according to the current position of the fast rolling door, and starts the drive motor to make the door curtain rise quickly. The door open signal opens again. As the name implies, the speed of a fast rolling door is very fast, and it cannot start and stop directly like a steel rolling gate. Generally, a frequency converter is required to control the speed of the motor. The faster the better, the better. When it is in place (about 20cm), a deceleration buffer stop process is needed to prevent impact on the track, prevent people from pinching, and reduce noise. This is also a standard to measure the performance of the fast rolling door.

3. There are two ways to locate the fast rolling door:

Mechanical positioning: This positioning method is similar to that of steel rolling gates, with the advantages of fast speed and low requirements for the controller.

Rotary encoder positioning: The elevators we often take are positioned with a rotary encoder. The advantage of this method is the accurate positioning. Taking the encoder with a resolution of 1024 as an example, the 3-meter high door is divided into nearly 9,000 points Theoretically, the accuracy can reach 0.3mm, and the height setting is simple. The fast rolling door control system designed by "Dongguan Xinyu" can set the height arbitrarily with only one button. This is very practical. Meters are enough to avoid opening in vain. If tall objects such as forklifts pass through, reset the height. The disadvantage is that the rotary encoder itself is relatively expensive, and it is a delicate component, and it needs to be used in conjunction with the PLC program, so the cost of the control system is relatively high.

Fourth, the development trend

fast rolling door has been popularized in developed industrial countries such as Europe, America and Japan for many years. Especially for production enterprises, there must be fast rolling doors between workshops. If it is a food or pharmaceutical company, it is mandatory by the government, and it must be isolated with a fast rolling door to prevent the product from being contaminated by secondary pollution. Just like our country mandates that certain industries must install fire doors (whether you like it or not), the factory must be put into production, and the factory will not start without fire door acceptance. The domestic fast-rolling door industry started late, but the development speed is very fast, with an annual increase of about 30%. Enterprises on the scale have gradually realized the consciousness of installing fast rolling doors. It is indeed very helpful to ensure product quality and reduce energy consumption. Second, it can improve the company's overall image.

The imported brands of fast-rolling doors mainly include: Homan, Kuofu, etc. The safety protection and quality performance of these foreign brands are good, but the price is extremely high, easily 57 thousand, and some up to 100,000, which is unbearable for ordinary users. In the final analysis, rapid rolling doors will not directly produce economic benefits, but nothing more than the effect of rapid isolation. Remove all unnecessary configuration that is icing on the cake, and keep the key necessary parts. Reliable quality, stable performance, safe and practical, and low-cost fast rolling doors are in line with China's national conditions.

As the country's requirements for food safety, drug safety and other fields become higher and higher, fast rolling doors will soon become a must-have equipment for enterprises. The professional design and development of fast rolling doors, professional production, fool installation, and unified industry standards will be an inevitable trend.

Five, the door concept

high-speed rolling door good thermal insulation and rapid opening and closing, not only reduces your energy costs, but also helps protect the environment and use valuable raw materials responsibly. In this way, we can give future generations a better future.

Quick door is a barrier-free isolation door with rapid lifting. Its main functions are heat preservation, moisturizing, dustproof, insect-proof, soundproof, etc., so that the workshop can maintain a constant temperature, constant humidity and clean working environment. It is suitable for food, medicine, electronics, rubber, chemical industry, automobile, textile, logistics and other fields.

2. Working principle

Quick door belongs to automatic control equipment, which is composed of door frame, PVC curtain, drive motor and control system. Fast rolling door

Lifting speed: 0.7m / s-2.1m / s, generally about 2 seconds from the bottom to the top (the speed is 20 times that of the electric rolling gate), vehicles and pedestrians do not need to wait, and do not constitute an obstacle.

There are many ways to trigger the door open signal: manual button, radar sensor, infrared photoelectric sensor, geomagnetic sensor, remote control, etc.

Door cloth material: PVC is generally used as the curtain cloth, PVC membrane material has better anti-aging performance, is not easy to fade, and has self-cleaning function. It is very suitable for fast rolling door. The origin is made in Germany or France. Thickness 0.8mm-2.0mm.

Color: orange, yellow, blue, silver, transparent, gray, etc. Orange is the first choice, because orange is very eye-catching, has a warning function, and has a certain anti-insect function.

Drive motor: The fast rolling door uses brake deceleration motor, which requires fast braking and low noise. Generally, the brake motors sold on the market are either not good in braking effect or very loud in braking noise, which are not suitable for fast rolling doors. A speed ratio of 1: 10-1: 15 is more appropriate.

Working process: The trigger signal is provided by the door opening sensor to the control system. The control system sends a command to the inverter according to the current position of the fast rolling door, and starts the drive motor to make the door curtain rise quickly. The door open signal opens again. As the name implies, the speed of a fast rolling door is very fast, and it cannot start and stop directly like a steel rolling gate. Generally, a frequency converter is required to control the speed of the motor. The faster the better, the better. When it is in place (about 20cm), a deceleration buffer stop process is needed to prevent impact on the track, prevent people from pinching, and reduce noise. This is also a standard to measure the performance of the fast rolling door.

3. There are two ways to locate the fast rolling door:

Mechanical positioning: This positioning method is similar to that of steel rolling gates, with the advantages of fast speed and low requirements for the controller.

Rotary encoder positioning: The elevators we often take are positioned with a rotary encoder. The advantage of this method is the accurate positioning. Taking the encoder with a resolution of 1024 as an example, the 3-meter high door is divided into nearly 9,000 points Theoretically, the accuracy can reach 0.3mm, and the height setting is simple. The fast rolling door control system designed by "Dongguan Xinyu" can set the height arbitrarily with only one button. This is very practical. Meters are enough to avoid opening in vain. If tall objects such as forklifts pass through, reset the height. The disadvantage is that the rotary encoder itself is relatively expensive, and it is a delicate component, and it needs to be used in conjunction with the PLC program, so the cost of the control system is relatively high.

Fourth, the development trend

fast rolling door has been popularized in developed industrial countries such as Europe, America and Japan for many years. Especially for production enterprises, there must be fast rolling doors between workshops. If it is a food or pharmaceutical company, it is mandatory by the government, and it must be isolated with a fast rolling door to prevent the product from being contaminated by secondary pollution. Just like our country mandates that certain industries must install fire doors (whether you like it or not), the factory must be put into production, and the factory will not start without fire door acceptance. The domestic fast-rolling door industry started late, but the development speed is very fast, with an annual increase of about 30%. Enterprises on the scale have gradually realized the consciousness of installing fast rolling doors. It is indeed very helpful to ensure product quality and reduce energy consumption. Second, it can improve the company's overall image.

The imported brands of fast-rolling doors mainly include: Homan, Kuofu, etc. The safety protection and quality performance of these foreign brands are good, but the price is extremely high, easily 57 thousand, and some up to 100,000, which is unbearable for ordinary users. In the final analysis, rapid rolling doors will not directly produce economic benefits, but nothing more than the effect of rapid isolation. Remove all unnecessary configuration that is icing on the cake, and keep the key necessary parts. Reliable quality, stable performance, safe and practical, and low-cost fast rolling doors are in line with China's national conditions.

As the country's requirements for food safety, drug safety and other fields become higher and higher, fast rolling doors will soon become a must-have equipment for enterprises. The professional design and development of fast rolling doors, professional production, fool installation, and unified industry standards will be an inevitable trend.

Five, the door concept

high-speed rolling door good thermal insulation and rapid opening and closing, not only reduces your energy costs, but also helps protect the environment and use valuable raw materials responsibly. In this way, we can give future generations a better future.

Recommended products

Last:Zipped Roll-up Door